Mead is an alcoholic drink made of honey. Let’s call it wine. The goal of this wine was to make a mead as it was in the beginning. Mead is also described as the drink of the gods. Nowadays mead is made in all kinds of ways. It can be a sweet desert wine, high in alcohol. It can be made as a champagne kind of wine, or it can made as a light, fresh white wine. I have been thinking a long time before I decided what I wanted to do with it. In ancient times the yeast would come from what was available in the air. Probably these yeasts would not produce more than 5% alcohol if you were very lucky. I am guessing that original mead from ancient times would be a very sweet drink with very little alcohol which also could not be kept a long time because it would be vulnerable for bacteria. Maybe it would become a sweet and sour drink.

This was not what I wanted. I decided that I would try to make a fresh wine with malic and citric acid and about 11% alcohol. A White wine for the summertime.

Here it is not possible to buy good quality honey. It is well known that honey from the supermarkets are part honey wth an added sugar solution. Unfortunately this is what you have to work with.

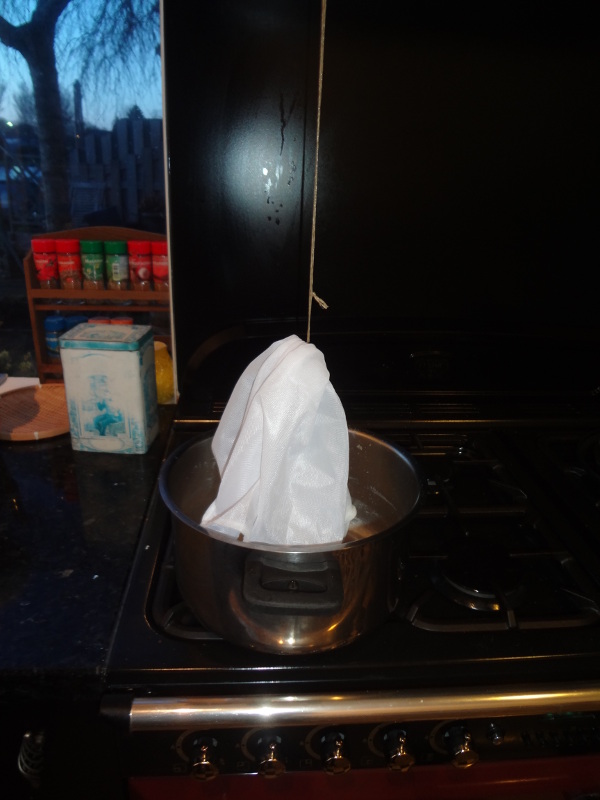

Anyway. First of all it is important to know how much sugar is in the honey. Obviously it is not possible to measure honey with the hydrometer. So I did the following.

- Put 100 gram honey in a bowl.

- Add water until it is total 1 liter

- Stir.

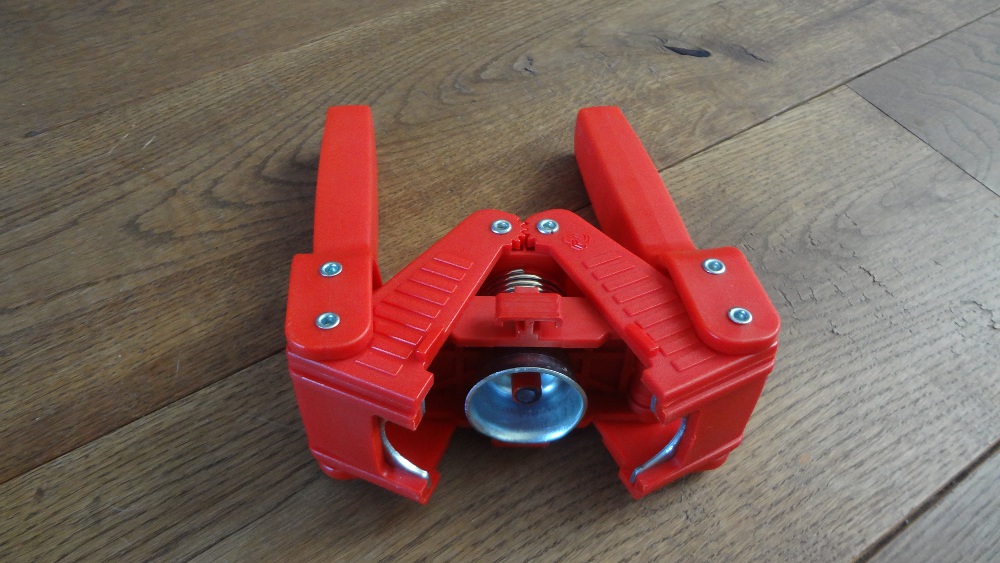

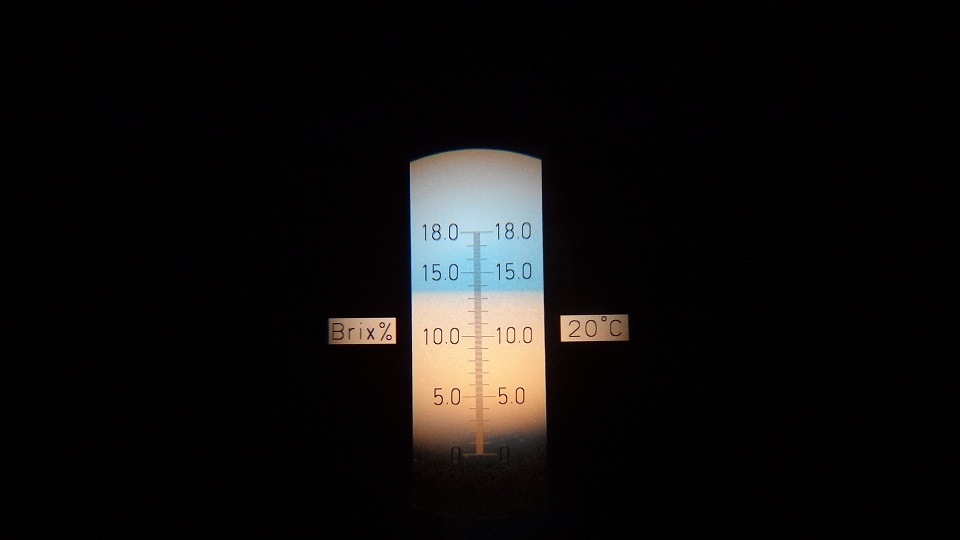

From this solution you can make a measurement with the refractometer or the hydrometer.

My measurement told me that there was 72 grams of sugar in the solution. Meaning that 100 gram of honey contains 72 gram sugar.

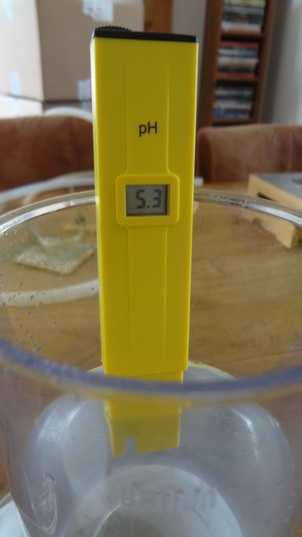

From that same solution I measured how much acid was in the honey. It turned out very low. Less than 2 grams per 100 grams of honey.

- I decided to make 20 liters of wine,

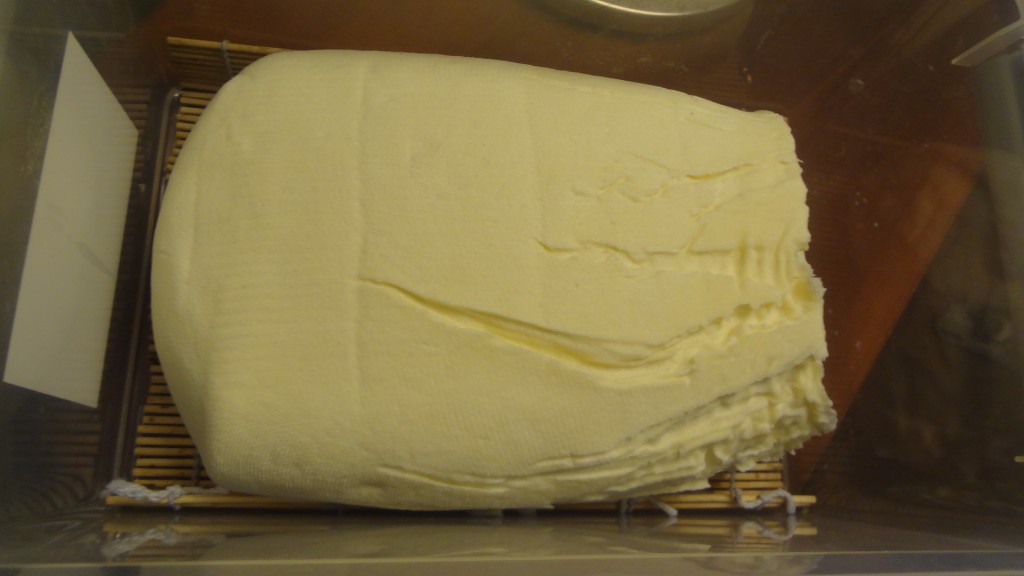

- I put 6 kg of honey in a fermenter and added water until 20 liter.

- I also added 40 grams of citric acid and 35 grams of malic acid. ( In case you don’t have malic acid you can use citric acid instead)

- Just in case I added some yeast nutrition.

- Stir with a long spoon so that everything is mixed properly and add normal White wine yeast. ( I had Bioferm Blanc so used that one.)

This is my basic recipe for mead.

However I wanted to experiment with it so I decided to divide the 20 liter in four 5 liter demijohns after the first stage of fermentation.

In the first I did not add anything. Just pure mead as a reference.

In the second I added some mint. ( Fresh)

In the third I added ginger and thyme. ( Fresh and spicy)

In the fourth I added 1 single pellet of hop. ( Fresh and aromatic)

You can see the amounts in the Picture. It is not much because the base should be mead with a taste of the added ingredient.

Now it is just waiting for the result.

For probably about 8 months…..

Hans

Türkçe çevirisi:

“BAL ŞARABI / MEAD / MEDE

İngilizce adı Mead olan ve baldan yapılan alkollü bir içecektir Bal Şarabı. Şarap literatüründe sadece üzümden elde edilenlere şarap adı verilse de gelin biz bu içeceğe de şarap diyelim ve özüyle tamlayalım: Bal şarabı. Hedefim ilk keşfedildiği zamanlardaki gibi bir bal şarabı yapmaktı. Eski çağlarda bal şarabı da tanrıların şarapları arasındaydı. Tanrılara lâyık, gözde bir içecekti. Günümüzde birçok formda ve tarifte bal şarabı üretiliyor:

- Alkol oranı yüksek tatlı şarap türü olarak çıkabilir karşınıza,

- Veya hafif ve şampanya/ köpüklü şarap formunda,

- Ya da hafif ve sek bir beyaz şarap olarak.

İşe koyulmadan önce istediğim form üzerine uzun süre düşündüm. Antik çağlarda maya havada/florada/yaşanılan ortamda mevcut olandan gelirdi. Kuvvetle muhtemeldir ki bu vahşi mayalarla en fazla % 5 alkol oranlı bir içecek elde edilebilir idi, ki o da çok şanslıysanız.

Tahminimce antik çağa has orijinal bal şarabı az alkollü ve oldukça tatlı bir içecekti ki düşük alkollü , dolayısıyla bakterilere açık oluşu nedeniyle uzun süre muhafaza edilemiyordu. Belki tatlı ekşi bir içeceğe dönüşüyordu.

Yapmak istediğim bu değildi. Bal şarabımın hafif, serinletici bir tazelik ve ferahlık veren sek bir şarap olmasını istiyordum. Malik asit ve sitrik asitle bu ferahlık hissini yakalayarak % 11 alkol oranlı sek bir beyaz şarap formunda yapmaya karar verdim. Yaz akşamları için ideal bir içecek yani.

Buralarda ( şehir yaşantısında) iyi kalite bal bulmak zor. Herkes biliyor ki süpermarketlerde satılan balların hemen hemen hepsi normal şeker katkılı. Lakin elde olanı kullanmaktan başka çareniz yok.

Her neyse. Öncelikle elinizdeki balın şeker oranını hesaplayarak işe başlayabilirsiniz. Doğaldır ki balın özgül ağırlığını yoğun formu nedeniyle hidrometre aracılığıyla ölçmek mümkün değil. Bu nedenle şöyle bir işlem yaptım:

- 100 gram balı bir kaba koydum,

- 1 litreye ulaşana dek su ekleyerek balı seyrelttim

- Ve iyice karıştırdım.

Elde ettiğiniz bu solüsyonun yoğunluğunu hidrometre veya refraktometre yardımıyla ölçebilirsiniz.

Elde ettiğim sonuç bana bu solüsyonda 72 gram şeker olduğunu söylüyordu. Yani elimdeki balın 100 gramında 72 gram şeker vardı.

Aynı solüsyonla elimdeki balda ne kadar asit olduğunu öğrenmek için asit testi de yaptım. Sonuç oldukça düşük çıktı : 100 gram balda 2 gramdan az asit bulunuyordu. Bu değerlere göre aşağıdaki reçeteyi hazırladım.

- Hedefim 20 litre bal şarabı elde etmekti.

- 6 kg balı fermentere koydum ve cetvel 20 litreye gelene dek su ekledim. 40 gram sitrik asit 35 gram da malik asit ekledim. ( Eğer elinizde malik asit yoksa yerine sitrik asit de kullanabilirsiniz.) N’olur n’olmaz diye bir miktar da maya besini ekledim. Mayayı eklemeden önce şıranın/şerbetin iyice karıştırdım. Tamamen homojenize olduğundan emin olduktan sonra beyaz şarap mayası ekledim. ( Elimde Bioferm Blanc vardı, onu kullandım.)

Bal şarabı için benim reçetem bu.

Temelde bal şarabı yapma hedefimin yanında bir kısmıyla da farklı aroma denemeleri yapmak istedim ve ilk fermantasyon sonrası 20 litreyi 4 adet 5’er litrelik damacanalara böldüm.

- Birincisine hiçbir şey eklemedim. Sade bal şarabı olacak. Aynı zamanda diğerleri için de referansım.

- İkincisine bir miktar taze nane ( Tazelik ve ferahlık için)

- Üçüncüsüne zencefil ve kekik ( Tazelik ve baharatlı bir aroma için)

- Dördüncüsüne ise bir pellet şerbetçiotu kattım ( Tazelik ve aromatik bir etki için)

Miktarları fotoğraflardan da görebilirsiniz. Çok fazla değiller. Yapmak istediğim ,eklenen malzemelerin tatlarını taşıyan bir bal şarabı zira.

Tüm işlemler sona erdi. Bundan sonrası sonucu beklemeye kalıyor.

Muhtemelen 8 ay kadar….

Hans “

Çeviren ve yorumlayan Sema Tanrıöver van Ameide